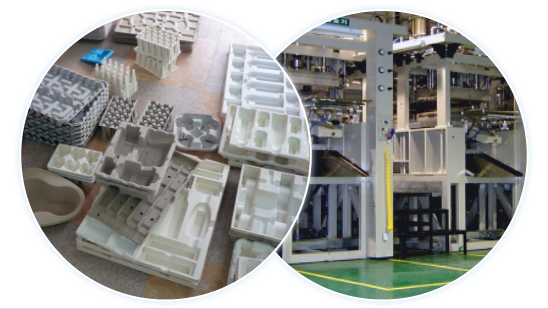

What is Dry Type ?

After molding a product at the bottom mold of a machine, the heat is added on the top in the first place, on the top and at the bottom in the second place, and on the top and at the bottom in the third place to dry the products inside the mold, therefore, products by dry type molding has accurate size and beautiful outward appearance.

Specification

| Description | TYPE OF MACHINE | ||

| IPP-720A | IPP-960A | IPP-1310A | |

| Number of Machine | 3Unit | 1Unit | |

| Mold Base Size WxL (mm) | 720mm x 600mm | 960mmx 700mm | 1.310mm x 1.100mm |

| Weight of Machine/Unit | 7.5TON | 12TON | 15TON |

| Height of Product | Standart 110mm (change Possibility) | ||

| Pressure(3rd upper) | 6~30TON | 75TON | 75TON |

| Cycle Time | 26~30sec | 28~30sec | 35~42sec |

| Source | AC, 380~415V, 50/60Hz, 3Ph | ||

| Electric Requirement | 450kW/3Unit | 650kW/3Unit | 400kW/1Unit |

| Pressing & Sliding System | Hydraulic | Hydraulic | Hydraulic |

| Heating | Electric Heater | ||

| Vacuum System | Liquid ring vacuum pump | ||

| Vacuum (mmHg) | ~710 mmHg (Maximum) | ||

| Power of Compressor HP) | 35HP/3Unit | 75HP/3Unit | 50HP/1Unit |

| Installation Area (WxLxH) | 20mx18mx6m/3Unit | 20mx20mx6m/3Unit | 6mx20mx6m/1Unit |

| Control System | PLC, Touch screen, CC Link, internet | ||

| Produce Method | Vertically operated 3 steps such as forming & drying system | ||

| Raw Materials | Waste paper, White board paper, Corrugated paper etc. | ||

{youtube}nIjfhJm_5-8{/youtube}